CINDERELLA

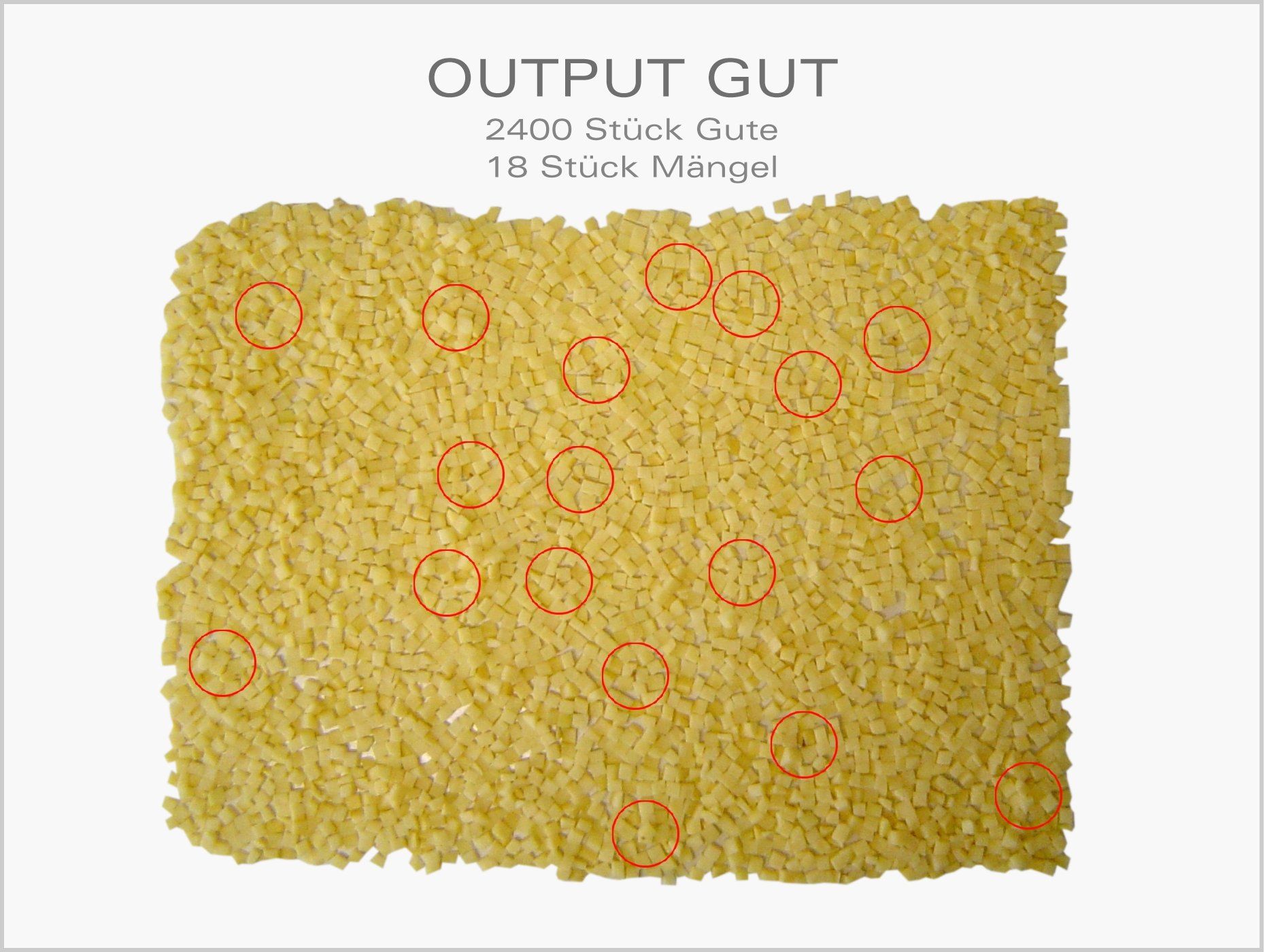

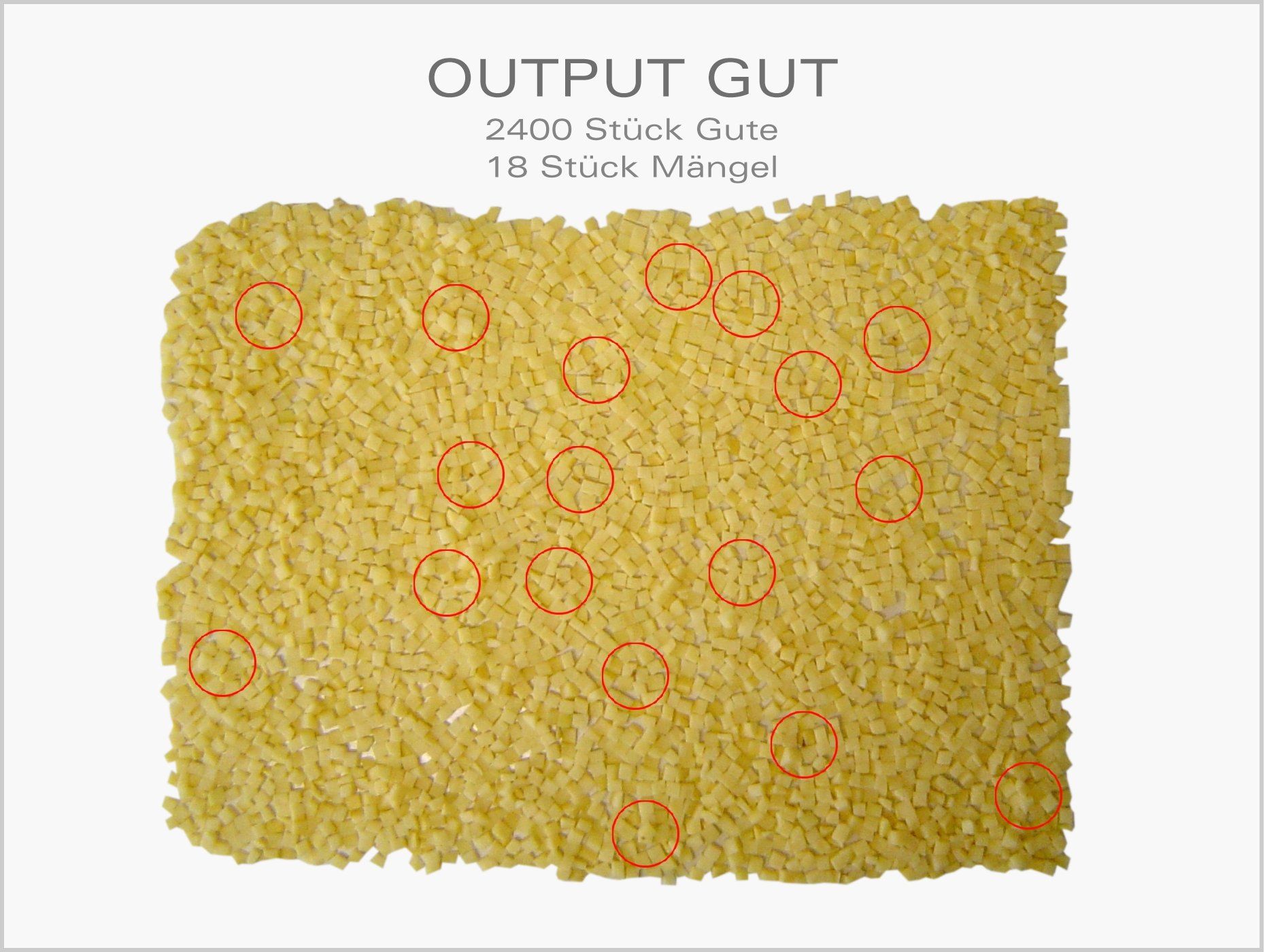

The Cinderella is an optical sorter for removing defective pieces from small or cut products. It has already helped many processing companies, large and small, save cost by reducing labour and improving product quality.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

info@shareteq.com

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

- Cost saving

Reduction in labour is the main objective of an optical sorter and the Cinderella removes 90% of inspection staff. Yield losses through sorting are very low compared to other systems.

- Quality improvement

Defective material is removed cleanly and consistently, leaving the finished product to your customer's specification without the subjective vaguaries of the human eye.

- Sorting criteria

Cinderella identifies defects by colour, to remove foreign bodies and discoloured product eg. browning on potato crisps, remaining peel on potato dice, greening on French fries etc.

- Simple to operate

The Cinderella is very high-tech but the operator doesn’t need to be. They get simple, clear statistical and operational information from the large colour touch screen which also provides live images of the product and defects allowing quick and easy set up or adjustment.

- You’re not on your own...

Help with set-up, software updates and fault diagnosis are available free of charge via an encrypted internet connection.

- Hassle-free

The simple hygienic design with easy access, coupled with remote service, gives the user many years of fault free service and very low downtime.

- Capacity

- 2 - 5 tonnes/hr depending on product size

- 2 sorted output channels

- Vision system

- High resolution colour cameras

- Unique lighting system reveals defects on underside

- Durable, power saving LED lighting with many years lifespan

- Automatic cleaning system maintains vision clarity during production

- Ejection system

- Close coupled compressed air nozzles for accurate rejection

- Nozzes separately selectable

- Automatic adjustment of grading pressure for individual programs

- Grading parameters

- Colour identification of red, green, brown and black, intuitive teaching for defect definition

- Operator interface

- Full HD 21” colour touch screen

- Easy, clear adjustment of sorting criteria

- Simple menu set-up for different end products

- Detailed statistical information

- Extensive control, fault monitoring

- Remote Service

- Connection by manufacturer via military grade encrypted VPN

- Complete remote control and diagnosis of faults

- Assistance with set-up and analysis of product and defect images

- Software updates and operational improvements without the need for skilled engineering back up

- Hygienic design

- Modern hygienic design

- Adjustable automatic self-cleaning system

- Tool free access for cleaning

- Suitable for the highest grade of food production

Get In Touch

Have a question? Need more information?

Thank you for getting in touch.

We will get back to you as soon as possible

Please try again later